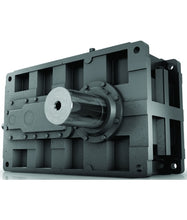

This product takes advantage of our many years of accumulated design expertise together with the use of high quality materials and components, and has the following features & benefits:

- Case hardened and ground helical gears, and hard finished spiral bevel gears have optimised gear geometry to maximise strength and efficiency, and to minimise noise and vibration.

- Horizontal split case design for ease of maintenance.

- Large diameter output shaft and bearings to maximize overhung load capacity.

- Innovative modular construction has minimised part count to maximise availability of product.

- Lip, Labyrinth and Face Seal on input, Lip Seal and Labyrinth on output shaft

- Vertical units have a Drywell sealing arrangement

- Spherical roller bearings throughout (tapers roller bearings on bevel pinion shaft)

- Large diameter output shaft, higher over hung loads

- Hollow bore and shrink disc options gives versatility in mounting

- External hold back, allows for inspection

- Atex compliant

- Better sealing for harsher environments

- No head of oil resting on the output seal

- Provides longer life

- Best option for stirrer applications

- Hollow bore reduces alignment issues

- Reduced down time

- Can be supplied against Group 2 or 3 for surface industries in designated Hazardous locations, Zones 1 and 2 for gases, vapours and mists and Zones 21 and 22 for dust.

Technical Specifications